The Power of Cold Forming for Metal Parts

- Adriana Gutierrez, Digital Media Producer

- 23 may 2025

- 4 Min. de lectura

Actualizado: 29 may 2025

In the world of metal manufacturing, achieving precision, minimizing material waste, and maximizing efficiency are constant pursuits. While processes like machining and hot forging have long been staples, a less commonly understood, yet incredibly powerful, alternative is cold forming. This transformative technology is gaining significant traction for its ability to produce high-strength, dimensionally precise metal parts with exceptional material savings and increased productivity.

For manufacturers in Santa Catarina, Nuevo Leon, and industrial hubs worldwide, understanding the capabilities and advantages of cold forming is key to unlocking new levels of competitiveness and innovation in metal parts production. Let's delve into what cold forming entails and why it's becoming a go-to solution for many applications.

What is Cold Forming?

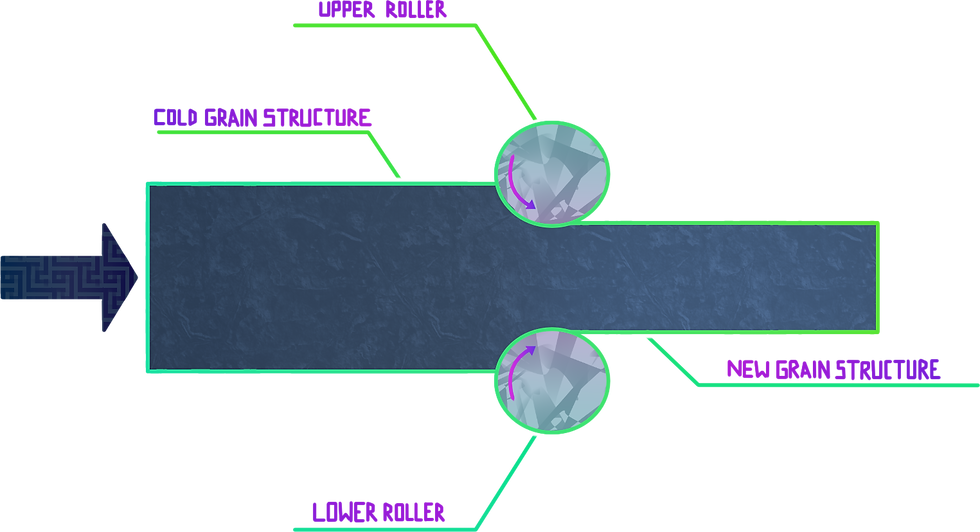

Cold forming, also known as cold forging or cold heading, is a metalworking process where a metal workpiece is shaped at or near room temperature, below its recrystallization temperature. Unlike hot forging, which relies on high temperatures to make the metal more malleable, cold forming uses extreme pressure to plastically deform the metal into the desired shape. This is typically achieved through stamping, bending, drawing, extrusion, or heading processes, often involving multiple dies and punches.

The key distinction is the temperature: by working with the metal cold, its inherent strength and structural integrity are maintained, and in many cases, even enhanced.

The Game-Changing Benefits of Cold Forming

The advantages of cold forming are significant and address many common challenges in traditional metal parts manufacturing:

Exceptional Material Savings (Near-Net Shape Production):

Less Waste

This is perhaps the most compelling benefit. Cold forming is a "net-shape" or "near-net-shape" process. Instead of cutting away material (like in machining), it deforms and redistributes the material, meaning significantly less scrap. For expensive materials, this translates directly into substantial cost reductions.

Optimal Material Utilization

The material is pushed and pulled into the desired shape, rather than removed, leading to almost 100% material utilization in some cases.

Superior Precision and Dimensional Accuracy:

Tight Tolerances

Working at ambient temperatures eliminates the issues of thermal expansion and contraction associated with hot processes. This allows cold formed parts to achieve very tight dimensional tolerances and excellent surface finishes, often reducing or eliminating the need for subsequent machining.

Repeatability

Once the dies are set, the process is highly repeatable, ensuring consistent part quality across large production runs.

Enhanced Mechanical Properties (Work Hardening):

Increased Strength and Hardness

As the metal is plastically deformed, it undergoes "work hardening" or "strain hardening." This process increases the yield strength, tensile strength, and hardness of the material, often eliminating the need for expensive secondary heat treatments.

Improved Fatigue Life

The grain structure of the metal is refined and aligned with the part's contour during cold forming, leading to improved fatigue resistance and overall part longevity.

High Efficiency and Productivity:

High Production Rates

Cold forming is typically performed on high-speed presses, enabling very rapid production cycles and high throughput rates, especially for large volumes.

Automated Potential

The consistent nature of the process makes it highly suitable for automation, further boosting efficiency and reducing labor costs.

Reduced Secondary Operations

Due to the precision and enhanced properties, many cold formed parts require minimal or no secondary machining, grinding, or heat treatment, streamlining the overall manufacturing process.

Excellent Surface Finish:

Smooth Surfaces

The cold deformation process can result in very smooth surface finishes, reducing the need for costly polishing or surface treatments.

Common Applications of Cold Forming

Cold forming is widely used across various industries for parts that require high strength, precision, and good surface finish. Some common examples include:

Automotive:

Bolts, nuts, screws, gears, shafts, valve components, spark plug shells, airbag canisters.

Aerospace:

Fasteners, specialized fittings.

Electronics:

Connectors, pins, battery components.

Industrial Machinery:

Bearings, rivets, various fasteners, machine components.

Consumer Goods:

Appliance components, hardware.

Challenges and Considerations for Implementing Cold Forming

While the benefits are compelling, implementing cold forming successfully requires careful consideration:

Higher Tooling Costs

The dies and punches used in cold forming must withstand immense pressure and precise tolerances, making them complex and expensive to manufacture.

Material Limitations

Not all metals are suitable for cold forming. Materials must have sufficient ductility to undergo plastic deformation without fracturing. Common materials include various steels (low carbon, medium carbon, alloy), aluminum alloys, copper, and brass.

High Initial Investment

The presses and equipment required for cold forming can represent a significant capital expenditure.

Design Complexity

Designing parts specifically for cold forming requires specialized knowledge to ensure the metal flows correctly within the dies.

Residual Stresses

Cold forming can introduce residual stresses into the part. While often beneficial (e.g., compressive stresses on the surface improving fatigue life), in some cases, post-forming stress relief might be necessary.

Why Cold Forming is Relevant for Today's Manufacturers

In a region like Santa Catarina, Nuevo Leon, with its robust automotive, appliance, and heavy machinery manufacturing presence, cold forming offers a direct pathway to:

Supply Chain Localization

Producing high-quality, cost-effective metal parts domestically reduces reliance on imports and strengthens local supply chains, aligning with nearshoring trends.

Global Competitiveness

The cost savings and quality improvements enabled by cold forming allow local manufacturers to compete more effectively on an international stage.

Sustainability Goals

Reduced material waste aligns perfectly with growing sustainability initiatives and environmental responsibility.

Technological Advancement

Adopting advanced manufacturing processes like cold forming positions companies at the forefront of industrial innovation.

Conclusion:

Cold forming is a sophisticated and highly effective metalworking process that delivers exceptional value. By transforming raw material into high-strength, precise components with minimal waste, it offers a compelling alternative to traditional manufacturing methods. For manufacturers seeking to unlock significant material savings, achieve superior part quality, and boost production efficiency, exploring the power of cold forming is not just an option—it's a strategic move towards a more precise, efficient, and profitable future.