Capacidades

Ofrecemos un conjunto integral de servicios, maquinaria y equipos diseñados para el corte y conformado precisos de láminas de metal. Nuestras capacidades incluyen:

-

Materias primas de primera calidad

-

Dos cizallas para metales avanzadas, capaces de manipular material de calibre 10 a 25 de hasta 12 pies de largo

-

Líneas de corte a medida completamente automatizadas para lograr precisión y eficiencia

-

Bobinas de acero con anchos de hasta 72 pulgadas y pesos de hasta 10 toneladas

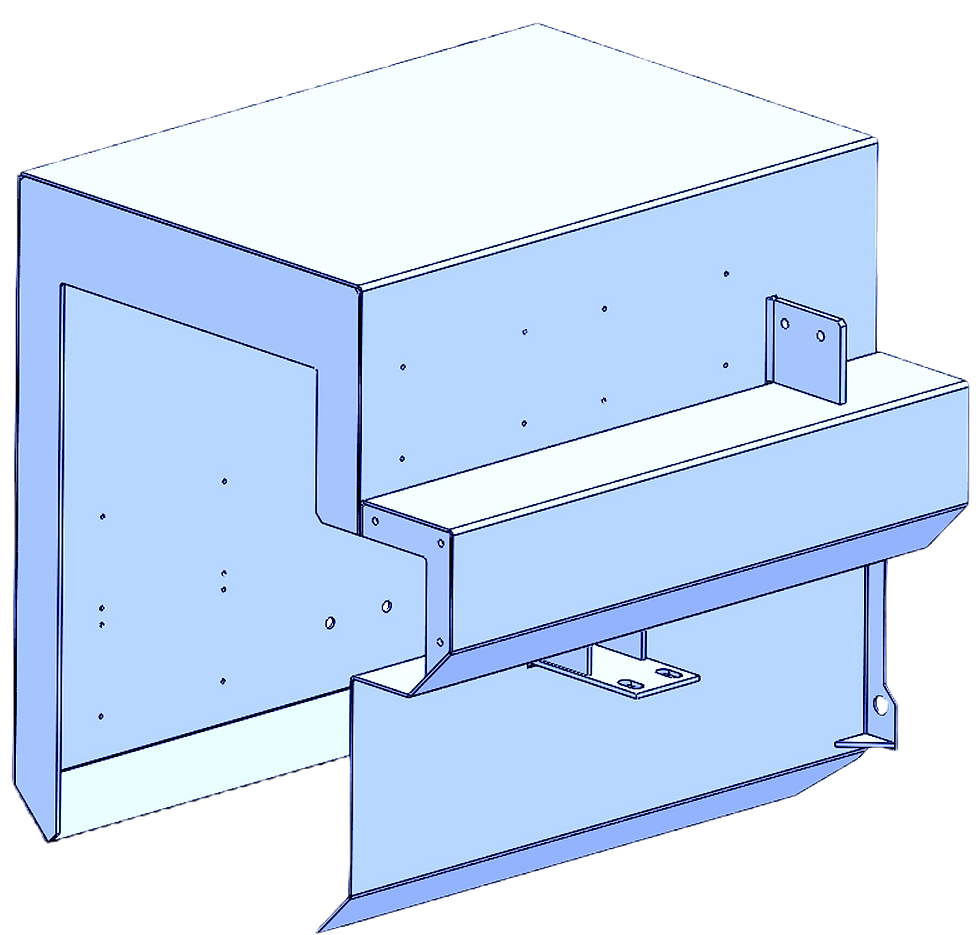

Planos de ingenieria

Dibujo Técnico

Nuestro equipo especializado crea dibujos técnicos detallados que sirven como modelo para sus piezas de metal. Mediante el uso de software y tecnología de última generación, nos aseguramos de que cada diseño se elabore meticulosamente para cumplir con las especificaciones exactas y los estándares de la industria. Esta atención al detalle en la fase de diseño sienta las bases para una producción precisa y eficiente.

Prototipado

Entendemos la importancia de la creación de prototipos en el proceso de desarrollo. Nuestros servicios de creación de prototipos permiten a los clientes probar y validar sus diseños antes de la producción a gran escala. Al crear prototipos de alta fidelidad, ayudamos a los clientes a identificar posibles mejoras y realizar los ajustes necesarios, garantizando que el producto final sea perfecto en todos los sentidos.

Ensamble

Nuestro equipo de profesionales experimentados garantiza que cada pieza se ensamble con precisión y siguiendo estrictos controles de calidad. Esto garantiza que el producto final no solo cumpla con las expectativas del cliente, sino que las supere.

Maquinaria

Láser

Maquinas de AMADA

-

VN3015AJE-6KR, 6000W Fiber (2025)

-

EN3015 AJMII, 3000W Fiber (2022)

-

ENSIS3015AJ, 6000W Fiber (2021)

-

LCG3015AJ , 2000W Fiber (2013)

Materiales

-

Steel 0.026” 1.000

-

SST 0.026” 0.500

-

Alum 0.040” 0.500

TuTurret Punch Amada (CNC)

-

AE2510NT 22T (2025)

-

EMK 3612 30T (2023)

-

EMK 3612 30T (2017)

-

EM 2510 20T (2004)

-

PEGA 358 30T (1999)

-

COMA 557 50T (1993)

TRUMPF Punch (CNC)

-

TruPunch 2000 – 20 ton (2016)

-

TruPunch 3000 S11 – 20 ton (2014)

Punzonado de Torreta

Prensas Plegadoras Eléctricas

-

1 Salvagnini PX.G4 (CNC 2025)

-

1 LVD DYNA Press 40/15 PRO 40T (CNC 2022)

-

2 LVD Electric 49” 24T 4 Axis (CNC 2016, 2017)

-

1 Amada Electric 49” 60T 8-Axis (CNC 2015)

-

1 LVD Dyna-Press 12/8 12T (CNC 2014)

Plegadoras Hidráulicas

-

1 Amada HRB 2204 220T 8 axis (CNC 2024)

-

1 LVD PPED 80/25 80T (CNC 2022)

-

2 LVD PPEB 80/25 80T (CNC 2022)

-

1 Amada HG 1303 130T 8 Axes (CNC 2022)

-

1 Amada Hydraulic 156” 220T 8 Axis (CNC 2017)

-

1 Bystronic hydraulic 144” 225T 4-Axis (CNC 2017)

-

1 Bystronic hydraulic 120” 100T 4-Axis (CNC 2017)

-

1 Amada HFE M2 1303 130T 8 Axes (CNC 2012)

Prensas Plegadoras

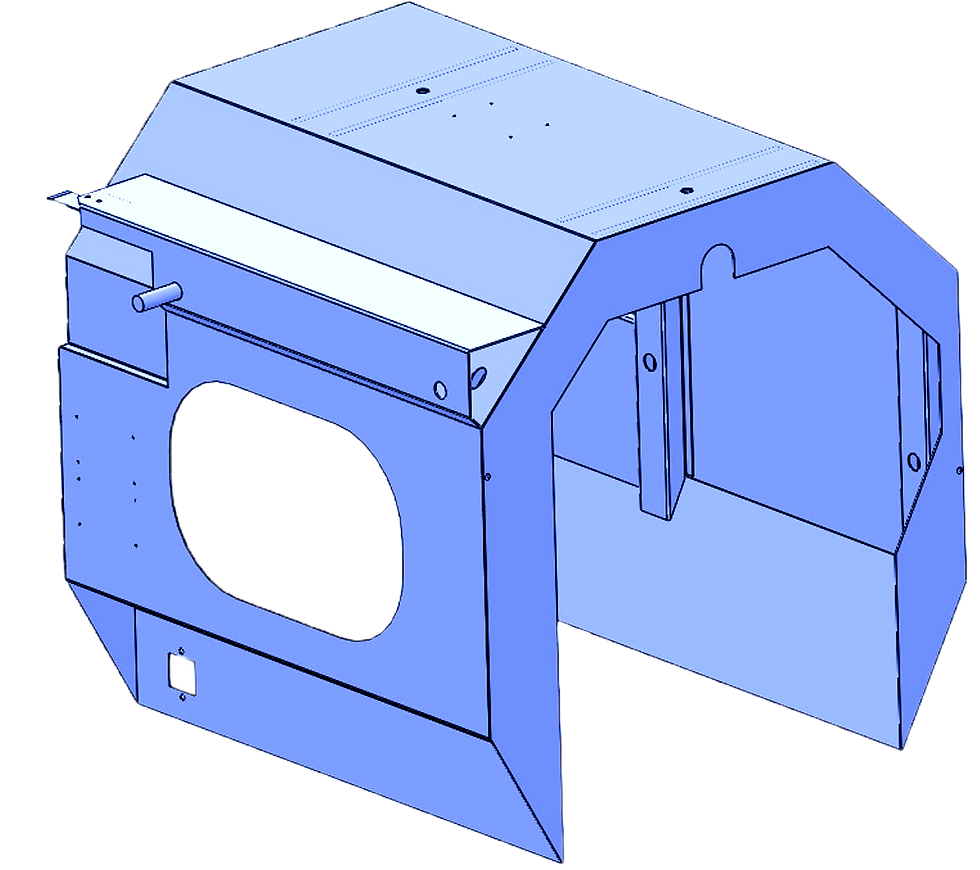

Líneas de ensamblaje y soldadura

En Tectron Metal, nuestro proceso de ensamblaje está diseñado para lograr precisión y eficiencia. Utilizamos moldes especializados para el ensamblaje, junto con técnicas avanzadas de perforación, roscado y PEM para garantizar que cada componente se ensamble de manera precisa y segura. Nuestros equipos de última generación y personal capacitado garantizan que cada pieza cumpla con los requerimientos solicitados.

Nuestro proceso de soldadura de microalambre con equipos Fronius y Lincoln garantiza soldaduras precisas y de alta calidad. Esta combinación de tecnología avanzada y personal calificado garantiza que nuestros componentes soldados cumplan con los más altos estándares de calidad.

Recubrimiento en polvo

En Tectron Metal, nuestros servicios de pintura en polvo brindan durabilidad y estética para sus productos metálicos. Nuestra línea de pintura está equipada para manejar piezas de hasta una longitud de 120", anchos de 30", altura de 60" y un peso de alrededor de 60 libras. Utilizando equipos avanzados y pinturas de proveedores reconocidos. Nuestro certificado UL en este proceso nos permite asegurar un acabado de acuerdo a las especificaciones solicitadas.

Ya sea por protección, durabilidad o estética, nuestra experiencia garantiza que sus piezas de metal cumplan con sus requerimientos.

Durabilidad

La calidad es la esencia de nuestras operaciones. La cual inicia desde el estudio de factibilidad, creación del prototipo, documentación del Proceso de aprobación de piezas (PPAP), estandarización de procesos y fabricación. Todo esto apoyado por nuestro sistema de gestión de calidad ISO 9001:2015.

Calidad

Nuestro proceso de envío se planifica y ejecuta meticulosamente, lo que garantiza que todos los productos se protejan con sumo cuidado e integridad. Nos esforzamos por entregar sus pedidos con prontitud y en perfectas condiciones, lo que refleja nuestra dedicación a la satisfacción y confiabilidad del cliente.

Envío

Sistema interno de gestión de producción (ERP)

En Tectron Metal, nuestro sistema de gestión de producción (ERP) es la piedra angular de nuestra excelencia operativa. Este sistema avanzado nos ayuda a gestionar los requisitos de materiales, administrar órdenes de producción y proporcionar fácil acceso a los datos.

Con seguimiento del 100 % de la materia prima, gestión del inventario base y gestión fluida de almacenes y kanban, nuestro ERP garantiza que todos los aspectos de la producción estén meticulosamente controlados.

Además, nuestro ERP agiliza los procesos de envío e incorpora códigos de barras para una mejor trazabilidad, garantizando que todos los productos se manipulen con precisión de principio a fin.

Requisitos de materiales

Administración de ordenes de producción

Fácil acceso a datos CAD

Seguimiento 100% de materia prima

Stock de inventario base

Gestión de almacenes y kanban

Procesos de envío

Códigos de barras disponibles

Proceso de producción

Requisitos del Cliente

Análisis de Viabilidad y Cotización.

Contrato de Relaciones Comerciales

Orden de Compra

Desarrollo y Aprobación de Prototipo

Fabricación

-

Compra y recepción de material.

-

Proceso de corte, punzonado y doblado.

-

Ensamble

-

Envío

Facturación y Pago