Top 8 Unique Properties of Advanced Alloys: Exploring Strength, Corrosion Resistance, and Heat Tolerance

- Adriana Gutierrez, Digital Media Producer

- Feb 19, 2025

- 3 min read

Updated: May 6, 2025

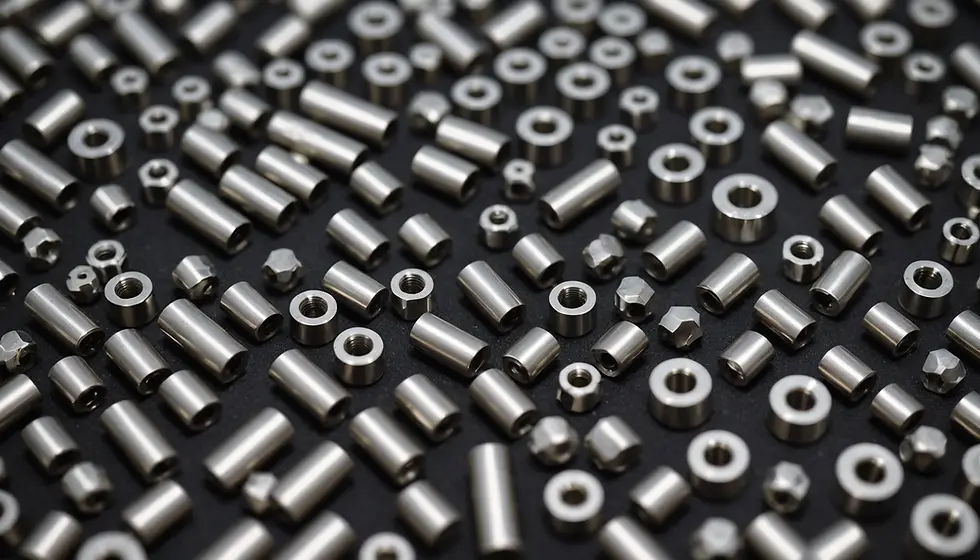

Advanced alloys, such as chromium, cobalt, nickel, hastelloy, inconel, waspaloy, rene, monel, aluminum, magnesium, titanium, zinc, copper, cast-irons and steels, play a vital role in modern industries, thanks to their outstanding characteristics. As developments in metallurgy progress, these materials are increasingly important in engineering, aerospace, medical devices, and more. In this article, we will explore the remarkable properties of advanced alloys, focusing on their strength, corrosion resistance, heat tolerance, and other unique features that make them essential across various applications.

1. Exceptional Strength

One of the most impressive traits of advanced alloys is their exceptional strength. For example, titanium alloys and steel alloys are engineered to be much stronger than the original metals they are derived from.

Aerospace components often rely on these high-strength materials to ensure structural safety at high altitudes and low temperatures. Specifically, titanium alloys can have tensile strengths of over 1,000 megapascals, which is about 50% higher than most steel alloys.

This combination of strength and lightweight properties allows engineers to create systems that maximize performance and efficiency without compromising safety.

2. Enhanced Corrosion Resistance

Corrosion resistance is crucial for many applications. Advanced alloys can withstand harsh environments that would typically lead to the deterioration of standard metals.

For instance, in marine environments, stainless steel and nickel-based alloys are used extensively because they resist saltwater corrosion. Studies show that using advanced alloys can extend the lifespan of marine structures by up to 50%, significantly reducing maintenance costs.

In the chemical processing industry, advanced alloys minimize the risk of equipment failure due to chemical erosion, ultimately saving companies thousands in repairs and downtime.

3. Superior Heat Tolerance

Advanced alloys also excel in heat tolerance. Alloys like Inconel can withstand temperatures up to 1,000 degrees Celsius while maintaining their mechanical properties. This is particularly important in applications such as aerospace engines and industrial furnaces.

By resisting thermal stresses, these heat-resistant alloys help prevent material failures in extreme environments, ensuring consistent performance in critical applications.

4. Fatigue Resistance

Fatigue resistance, or the ability to endure cyclic loading, is vital for materials used in demanding applications. Advanced alloys are designed with specific microstructural enhancements that improve their fatigue resistance.

For example, components in the aerospace and automotive industries, such as engine parts and landing gear, must endure continuous stress over time. Advanced alloys can have fatigue life improvements of up to 40% compared to standard materials, decreasing the need for frequent replacements and maintenance, which is crucial for operating costs.

5. Excellent Weldability

Weldability is essential in construction and manufacturing. Certain aluminum and titanium alloys offer excellent weldability, making them easy to join and fabricate into complex structures.

In the shipbuilding industry, for instance, the ability to quickly weld alloys can speed up production timelines by up to 30%, significantly reducing costs. Strong welded joints maintain overall material integrity, which is essential for safety and performance in construction.

6. Improved Wear Resistance

Wear resistance is another key characteristic of advanced alloys. These materials resist abrasion, erosion, and surface wear, making them ideal for environments where high friction occurs.

In the mining industry, specialized wear-resistant alloys can last up to three times longer than conventional materials, resulting in reduced downtime of machinery and lower repair costs. This extended lifespan enhances overall efficiency and productivity.

7. Diverse Thermal Conductivity

Advanced alloys offer diverse thermal conductivity properties, which allows them to manage heat transfer effectively in various applications.

For example, copper alloys are known for their excellent thermal conductivity, essential for electronics cooling systems, while certain steel alloys retain heat for specific applications. The flexibility to tailor these thermal properties according to specific requirements is a valuable advantage in engineering.

8. Tailorability and Customization

The ability to customize advanced alloys for specific applications sets them apart. Processes such as alloying, heat treatment, and surface modifications enable engineers to modify their strength and thermal properties.

For instance, in the oil and gas industry, alloys can be tailored to withstand harsh underwater conditions and high pressures. This adaptability is critical as specialized materials become more necessary to support innovations across different sectors.

Final Thoughts

The unique characteristics of advanced alloys—such as strength, corrosion resistance, and heat tolerance—are essential in various industries. As technology advances, the demand for these materials will likely increase, leading to ongoing innovations in metallurgy.

Understanding the distinct properties of advanced alloys helps in making informed decisions about material selection and application. Whether in aerospace or automotive sectors, these materials are positioned to continue playing a significant role in future advancements.

With their combination of strength, durability, and customization options, advanced alloys are foundational to achieving sustainability and efficiency in modern manufacturing and engineering.