Capabilities

We offer a comprehensive suite of services, machinery and equipment designed to precisely cut and form sheet metal. Our capabilities include:

-

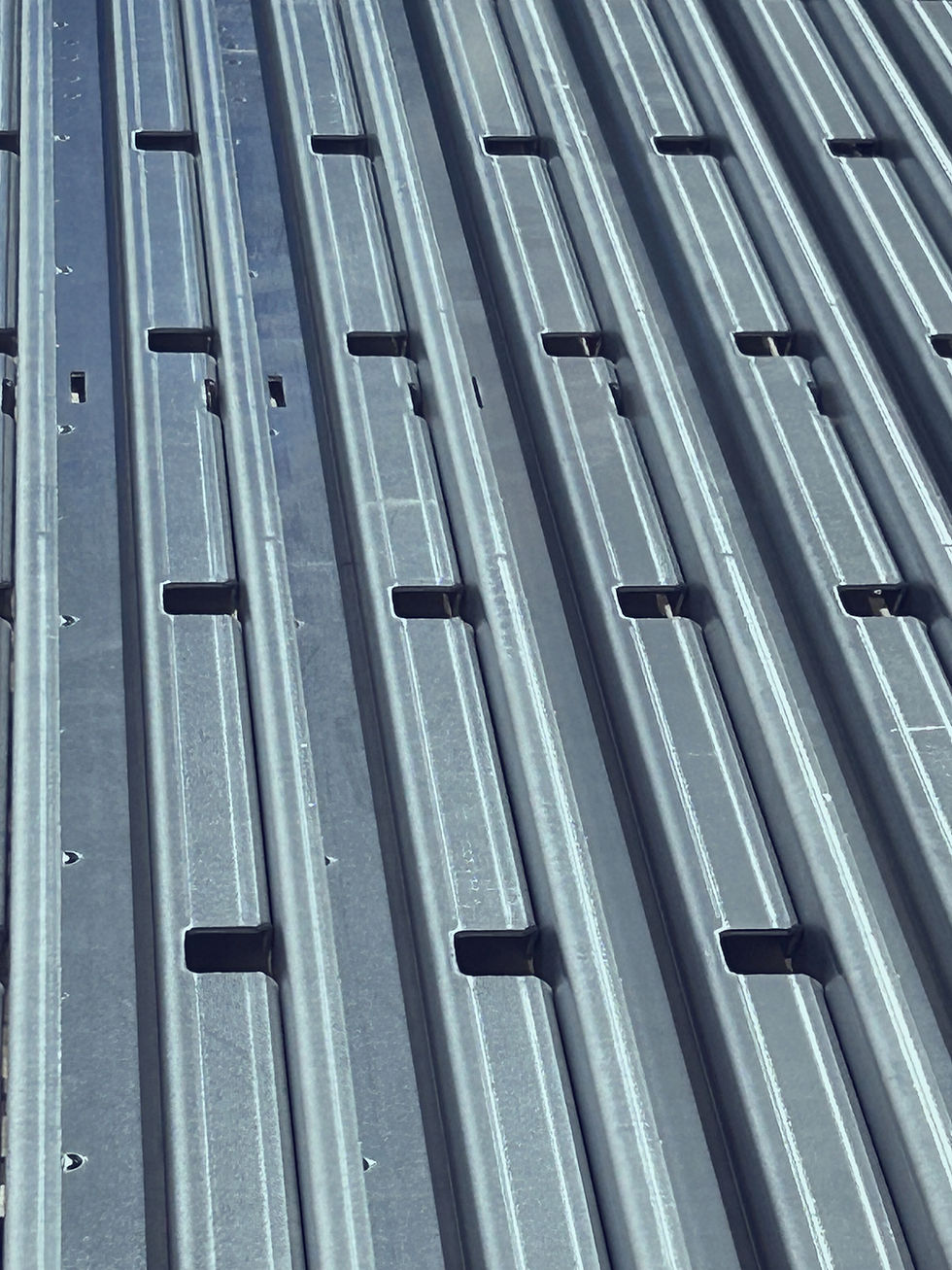

Premium raw materials for superior quality

-

Two advanced metal shears, capable of handling 10 to 25 gauge material up to 12 feet long

-

Fully automated cut-to-length lines for accuracy and efficiency

-

Steel coils with widths up to 72 inches and weights up to 10 tons

Engineering Plans

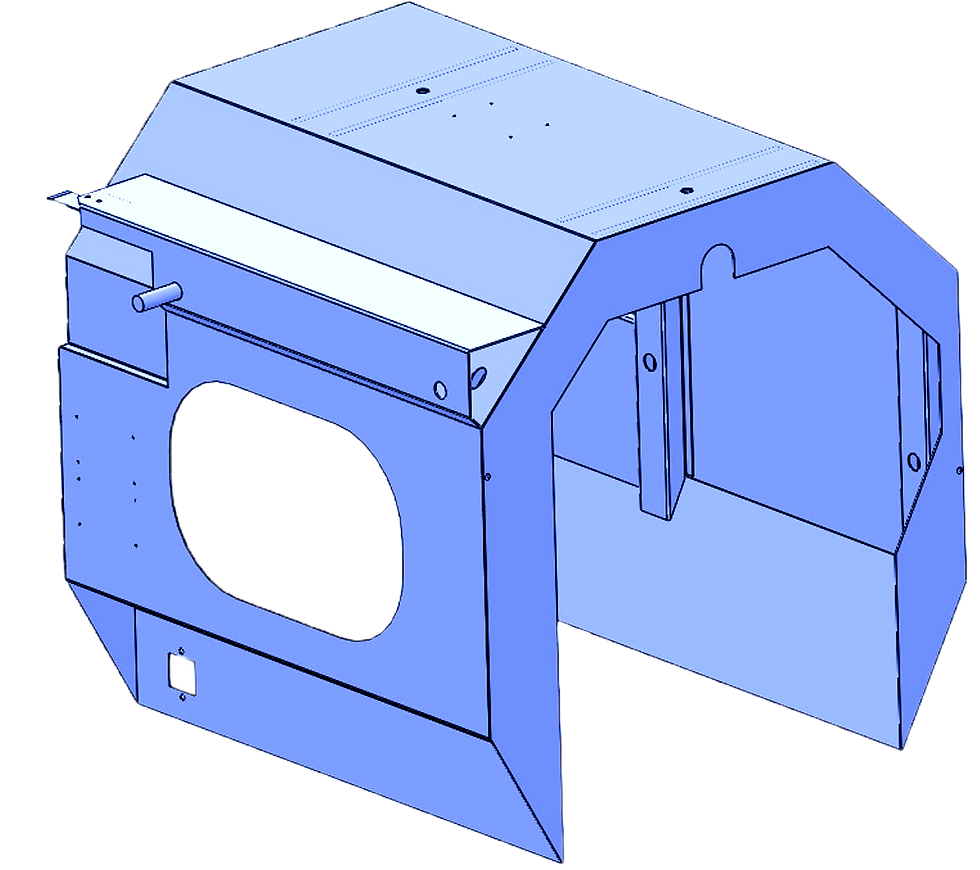

Drafting

Our skilled team creates detailed technical drawings that serve as the blueprint for your metal parts. Using state-of-the-art software and technology, we ensure that every design is meticulously crafted to meet exact specifications and industry standards. This attention to detail in the drafting phase sets the foundation for accurate and efficient production.

Prototyping

We understand the importance of prototyping in the development process. Our prototyping services allow clients to test and validate their designs before full-scale production. By creating high-fidelity prototypes, we help clients identify potential improvements and make necessary adjustments, ensuring that the final product is perfect in every way.

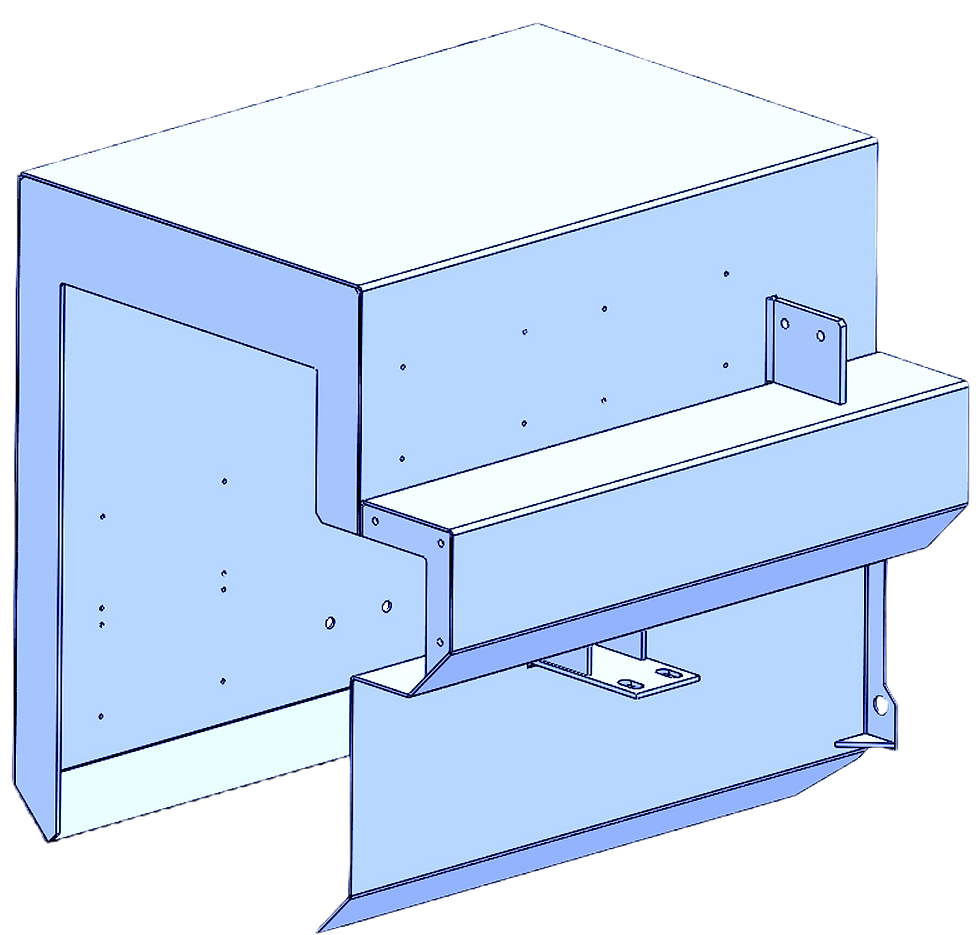

Assembly

Our team of experienced professionals ensures that each part is assembled with precision, adhering to strict quality control measures. This guarantees that the final product not only meets but exceeds client expectations.

Machinery

Laser

AMADA Machines

-

VN3015AJE-6KR, 6000W Fiber (2025)

-

EN3015 AJMII, 3000W Fiber (2022)

-

ENSIS3015AJ, 6000W Fiber (2021)

-

LCG3015AJ , 2000W Fiber (2013)

Materials

-

Steel 0,026” 1,000

-

SST 0,026” 0,500

-

Alum 0,040” 0,500

TuTurret Punch Amada (CNC)

-

AE2510NT 22T (2025)

-

EMK 3612 30T (2023)

-

EMK 3612 30T (2017)

-

EM 2510 20T (2004)

-

PEGA 358 30T (1999)

-

COMA 557 50T (1993)

TRUMPF Punch (CNC)

-

TruPunch 2000 – 20 ton (2016)

-

TruPunch 3000 S11 – 20 ton (2014)

Turret Punching

Electric Press Brakes

-

1 Salvagnini PX.G4 (CNC 2025)

-

1 LVD DYNA Press 40/15 PRO 40T (CNC 2022)

-

2 LVD Electric 49” 24T 4 Axis (CNC 2016, 2017)

-

1 Amada Electric 49” 60T 8-Axis (CNC 2015)

-

1 LVD Dyna-Press 12/8 12T (CNC 2014)

Hydraulic Press Brakes

-

1 Amada HRB 2204 220T 8 axis (CNC 2024)

-

1 LVD PPED 80/25 80T (CNC 2022)

-

2 LVD PPEB 80/25 80T (CNC 2022)

-

1 Amada HG 1303 130T 8 Axes (CNC 2022)

-

1 Amada Hydraulic 156” 220T 8 Axis (CNC 2017)

-

1 Bystronic hydraulic 144” 225T 4-Axis (CNC 2017)

-

1 Bystronic hydraulic 120” 100T 4-Axis (CNC 2017)

-

1 Amada HFE M2 1303 130T 8 Axes (CNC 2012)

Press Brakes

Assembly & Welding Lines

At Tectron Metal, our assembly process is designed to achieve precision and efficiency. We use specialized molds for assembly, along with advanced drilling, threading, and PEM techniques to ensure each component is assembled accurately and securely. Our state-of-the-art equipment and trained personnel ensure that every part meets the required specifications.

Our wire welding process using Fronius and Lincoln equipment ensures precise, high-quality welds. This combination of advanced technology and skilled personnel guarantees that our welded components meet the highest quality standards.

Powder Coating, Quality, & Shipping

At Tectron Metal, our powder coating services provide durability and aesthetic appeal for your metal products. Our coating line is equipped to handle parts up to 120" in length, 30" in width, 60" in height, and approximately 60 pounds in weight. We use advanced equipment and paints from reputable suppliers. Our UL certification for this process ensures a finish that meets the requested specifications.

Whether for protection, durability, or aesthetics, our expertise ensures that your metal parts meet your specifications.

Durability

Quality is the essence of our operations. It begins with the feasibility study, prototype creation, documentation of the Production Part Approval Process (PPAP), process standardization, and manufacturing. All of this is supported by our ISO 9001:2015 quality management system.

Quality

Our shipping process is meticulously planned and executed to ensure that all products are protected with the utmost care and integrity. We strive to deliver your orders promptly and in perfect condition, reflecting our commitment to customer satisfaction and reliability.

Shipping

Proprietary Production Management System (ERP)

At Tectron Metal, our proprietary Production Management System (ERP) is a cornerstone of our operational excellence. This advanced system aids us in managing material requirements, administering production orders, and providing easy access to CAD data.

With 100% raw material tracking, base inventory stock management, and seamless warehouse and kanban management, our ERP ensures every aspect of production is meticulously controlled.

Additionally, our ERP streamlines shipping processes and incorporates barcodes for enhanced traceability, guaranteeing that all products are handled with precision from start to finish.

Material Requirements

Administration of Production Orders

Easy Access to CAD Data

100% Raw Material Tracking

Base Inventory Stock

Warehouse and Kanban Management

Shipping Processes

Barcodes Available

Production Process

Customer Requirements

Feasibility Analysis and Quote

Commercial Relations Contract

Purchase Order

Development and Approval of Prototype

Fabrication

-

Purchase and receiving of material

-

Sheering, punching, and bending process

-

Assembly

-

Shipping

Invoicing and Payment